Telecommunication

With the approaching commercialization of 5G communication networks, the operating frequency of communication equipment has reached the range of 6GHz-40GHz. Such high operating frequency brings new requirements to design engineers for shielding design and thermal management. Meanwhile, the basic hardware products in the communication equipment manufacturing industry present the development trends to high speed, compactness, lightweight and manufacturing automation. These changes and requirements make increasingly higher heat dissipation requirements and EMC requirements for telecommunication equipment. JONES has accumulated a great deal of successful experience in the telecom industry, so as to create a full range of products for the industrial customers in the field of thermal management materials and EMC. The use of shielding and filtering technology for RRU mobile communication base stations, RF filters, high-end routers, high-speed optical modules and other devices greatly solves EMC interference problem in equipment or system. The customized and developed wave filter parts, ultra-soft FIP points rubber, special conductive sealing materials, wave absorbing materials, waterproof breathable valves and other products provide excellent solutions for equipment that to adapt various complex electromagnetic environments. The thermal gel developed by application of high-end thermal management materials can meet the needs of production automation. In addition, the thermal pad, thermal grease, synthetic graphite sheet and PCM with high thermal conductivity can meet the requirements for high heat dissipation.

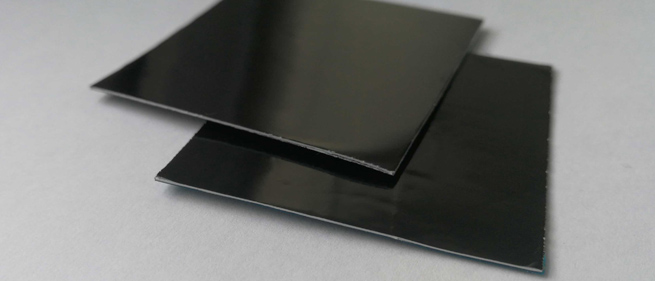

TIM low-density synthetic graphite sheet and natural graphite

200μm low-density synthetic graphite can be used as thermal interface material. Compared with traditional thermal grease, phase change material and thermal pad, synthetic graphite film has high thermal conductivity, stable quality and less aging problem. Low-density synthetic graphite films are supplied in sheet or die-cut form and are widely used in power electronics and communication equipment.

Natural graphite

Natural graphite is an interface material with high thermal conductivity and high flexibility. It is made entirely of natural graphite without any filler or binder components. It is ideal thermal interface material for power devices and heat sinks designed in a limited space. It can be used continuously at temperatures above 400 °C. It optimizes the thermal performance of the device, keeps the power device in good contact with the heat sink, and it can be made into sheets, rolls or die cut into customizable shapes with or without pressure sensitive adhesive (PSA).

Heat storage PCM

Heat Storage PCM is a type of thermal management material with high heat storage, which consist of silicone matrix filled with microcapsulated powder.This material can be provided in different forms such as sheet, GEL and potting glue. Enthalpy value of Heat Storage PCM ranges from 100 to 160J/g with phase change material options of 37°C and 43°C。It is suitable for various application scenarios. Thermal storage phase change materials are widely used in microprocessors, chips and power module modules due to their high energy storage enthalpy.

Thermal conductivity PCM

Thermal Conductivity PCM is a solid sheet at room temperature. When the device’s operating temperature is reached, the material softens and covers the surface of the device to achieve a low thermal resistance TIM material. Phase change materials provide in rolls for ease of processing and assembly. It has better reliability than thermal grease. When the phase change temperature is reached, the material is fully phase changeable and can be used in very thin BLT designs. Thanks to its low thermal resistance, thermal conductivity PCM is widely used in microprocessors, chips and power modules.

Thermal grease

Thermal Grease is a thermally conductive composite that has better fluidity and can be applied on a heat source by dispensing, printing, etc., and is suitable for smaller gaps or zero gaps design. Thermal grease has a very low thermal resistance due to its very thin BLT.

Thermal gel

Thermal GEL is a kind of thermal conductive composite with a certain fluidity, which can be applied to heat-generating devices by means of dispensing, with higher assembly efficiency and suitable for automated production lines. GEL-state thermal conductive products have lower thermal resistance, better compression set performance, less compressive stress, and are suitable for applications in which different heat-generating devices share a common heatsink.

Thermal pad

Thermal Pad is a thermal conductive composite material with a certain thermal conductivity and flexibility. It is mainly used for gap filling between semiconductor devices and heat sinks, and improves the transfer efficiency of the heat generated by semiconductorsvduring operation.

Form in place

FIP conductive rubber gasket (form-in-place) can automatically dispense high-conductivity rubber on metal or plastic substrate to form EMI shielding gasket according to customer’s different design with computer-aided programming dispensing equipment.The gasket is made by filling different conductive particles in a silicone rubber. It has good elasticity and cured at a high temperature to form an electromagnetic and environmental sealing material. Our company can provide FIP materials with different packaging and different hardness according to different shielding performance requirements of customers, and can provide a total solution for conductive FIP products.

Wave absorbing rubber

The microwave absorbing rubber sheet is a functional polymer material independently developed by our company. Through adding absorbing particles in the elastomer, microwave absorbing rubber sheet has good electromagnetic wave absorption effect. Formulations are tuned according to the specified frequency ranges from 1 to 40 GHz through independently developed recipe adjustments. Depending on the customer’s specific application scenario, the absorbing materials range offers standard sheet and customized die cut shapes.

Conductive rubber material

The conductive rubber material is a type of polymer material which is independently developed by our company by filling conductive particles in silicone rubber. It has good EMI shielding effect and excellent water/steam sealing and corrosion resistance. Thanks to the independently developed formulation, Jones’ conductive rubber products to have a wider operating temperature range and a longer service life. According to the customer’s specific application scenarios, JONES’s conductive rubber series can provide: compression molded gasket, extruded rubber strip, co-extruded conductive rubber strip, coated conductive rubber strip and so on.

Fabric over foam

FOF consists of conductive fabric layer and foam core, which can be processed into various shapes. The compressibility and resilience of foam core can meet the requirements of low sealing force. It is widely used in EMI protection of electronic equipment’s housing and provides EMI shielding at the cabinet gap.

Waterproof breathable valve

Waterproof and breathable valve with a fine porous structure of expanded polytetrafluoroethylene (ePTFE) waterproof and dustproof gas-permeable membrane to prevent water droplets, dust, fine debris, fine salt crystals, oil droplets and other chemicals while maintaining good air pressure balance difference between the inside of the housing and the environment in which it is located, thereby protecting the stress on the sealing strip and preventing its aging and failure. Suitable for telecommunication devices that operate in harsh environments, as well as telecommunication devices with built-in batteries.

Full-conductive foam

Three-way conductive foam—-Ni-plated PU foam provides good electrical conductivity while maintaining low compressive stress and high deformation characteristics. It is not limited to the outer conductive structure as that of traditional FOF gasket,can be designed according to the application required dimension without affecting the conductivity.

Vapor chamber

Vapor Chamber is a vacuum cavity with a fine structure on the inner wall. The purpose of heat dissipation is achieved through the vaporization and condensation of the cooling liquid in the cavity, which is usually used for electronic products that require a small volume or need to quickly dissipate high heat.

Heat pipe

The heat pipe is a kind of heat-conducting material. It makes full use of the heat-conducting principle and the fast heat-transfer properties of the phase-change medium to quickly transfer the heat of the heating object to the outside. Its thermal conductivity of heat pipe exceeds that of any known metal.